Product Introduction

The air filter element of the generator set uses negative pressure to absorb welding fumes and welding fumes into the welding fume purifier equipment. Large particles of sparks are first blocked by the fire screen. Tiny dust particles are filtered by the filter cartridge, and large particles of dust will directly fall to the dust collection drawer. Particulate dust will adhere to the surface of the filter cartridge. After filtering, the clean air fine filter element will enter the clean room and then be filtered and discharged by activated carbon cotton. The cleaning steps and methods of the filter cartridge of the dust removal and welding smoke purifier are as follows: first, unscrew the nut of the filter cartridge cover, remove the filter element, place it vertically in a position where dust can be collected, and tap the inside of the filter cartridge with a small stick to make the dust attached to the outer wall of the filter cartridge fall. The effect of dust treatment can be achieved by beating with small rods in the folds on the outside of the filter cartridge. The filter cartridge of some single machine welding fume purifier is a washable filter cartridge. Remove the filter cartridge, both hands carry the sealed end of the filter cartridge and immerse it in clean water for a moment, bring it up and repeat it many times, which can achieve the purpose of cleaning the dust on the filter cartridge. Can be reused after drying. In addition, gas can also be used to blow back. The pulse-type welding smoke purifier only needs to turn on the pulse dust removal function, and the machine will realize automatic back-blowing dust removal. After the pulse dust removal is completed, it can directly pull out the dust accumulation drawer.

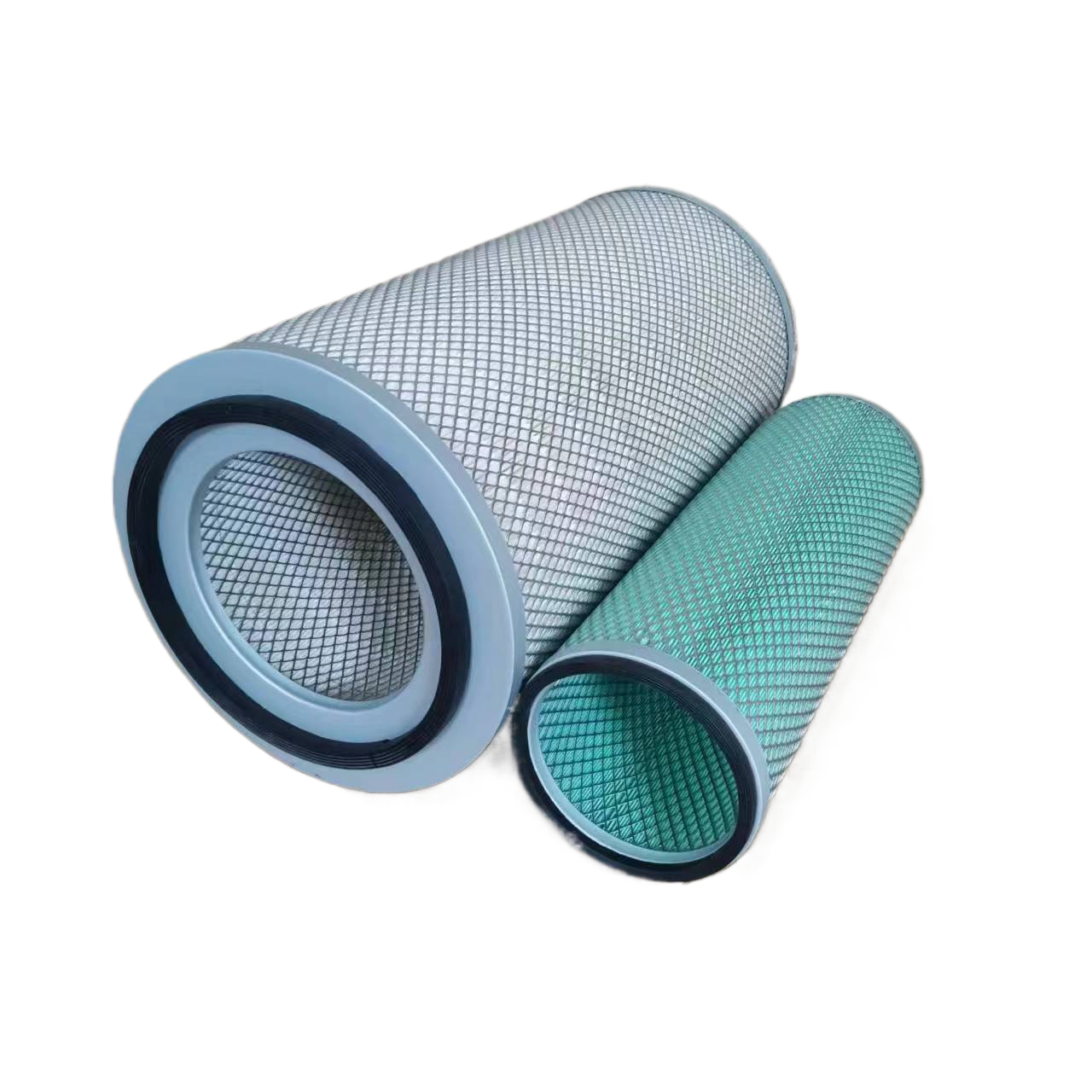

Generator air filter performance characteristics: suitable for powder spraying, sandblasting operations, pigment industry, wood processing filtration. 1. Imported long fiber polyester filter material, the fibers are interlaced and evenly distributed. 2, good wear resistance, more than the traditional filter material can withstand the air flow pulse blowback. 3. The filter material has good stiffness and can be cleaned. 4. The end cover and the central frame are all electro-galvanized parts without rust. 5. Sealed closed-cell elastic neoprene.

When purchasing a generator set filter, you should pay attention to several points: domestic or imported filter materials should be selected, including coated polyester non-woven fabric (for oil-proof, anti-static and flame-retardant treatment), polyester long fiber filter paper, glass fiber filter materials, etc., and adopt wide pleat discount technology for high temperature resistant dust removal filter element, with uniform gap; The end covers at both ends of the dust removal filter element shall be stamped with anti-rust steel plate with thickness of 0.8mm (not easy deformation), the bonding part between the end cover and the filter material shall be bonded with special polyurethane foaming adhesive (to ensure that the end cover and the filter material are tightly connected without gaps); The inner and outer support protection frames are all punched stainless steel plates with high strength and good corrosion resistance over 0.5mm, and the dust removal filter element with large support strength is blown and blown and sucked. The connection between the dust removal filter element and the sliding plate is sealed with low hardness and high strength foaming rubber sealing rubber ring to ensure no dust leakage, and filtration accuracy of 99.99; the internal and external protective nets and internal filter materials are fixed by advanced automatic spiral casting glue machine (or fixed with fastening belt) to ensure uniform air volume and filter area of the dust removal filter element, which is convenient for the electromagnetic pulse valve to blow back and clean the dust.

Tag:

AF872 generator set air filter element

Applicable model:

AF872

Product Classification: